Bolt Type Copper Aluminum Terminal Lug

Product Specifications

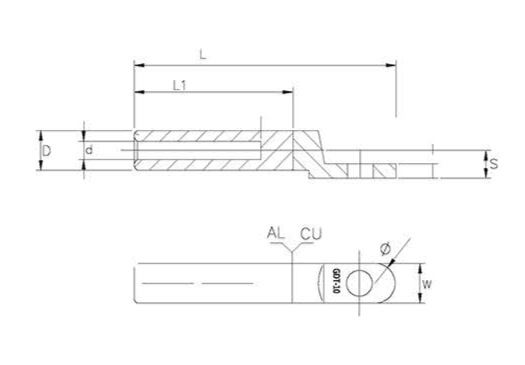

| Item No. | D+0.2 | d+0.2 | L+2 | L1+2 | S+0.2 | Ø+0.3 | W+0.2 |

| CBL-10 | Ø 10 | Ø 4.5 | 40 | 66 | 7 | 6.5 | 10 |

| CBL-16 | Ø 10 | Ø 5.5 | 40 | 66 | 7 | 6.5 | 10 |

| CBL-25 | Ø 12 | Ø 7 | 45 | 72 | 8 | 8.5 | 13 |

| CBL-35 | Ø 14 | Ø 8.5 | 51 | 80 | 9 | 8.5 | 14 |

| CBL-50 | Ø 16 | Ø 9.5 | 87 | 54 | 10 | 8.5 | 16 |

| CBL-70 | Ø 18 | Ø 12 | 95 | 59 | 11 | 8.5 | 20 |

| CBL-95 | Ø 21 | Ø 13 | 102 | 62 | 12.5 | 10.5 | 20 |

| CBL-120 | Ø 23 | Ø 15 | 105 | 65 | 13.5 | 10.5 | 22 |

| CBL-150 | Ø 25 | Ø 16 | 112 | 67 | 14.5 | 10.5 | 25 |

| CBL-185 | Ø 27 | Ø 18 | 121 | 70 | 15.5 | 13 | 28 |

| CBL-240 | Ø 30 | Ø 20 | 124 | 73 | 17 | 13 | 30 |

| CBL-300 | Ø 34 | Ø 23 | 133 | 78 | 19 | 13 | 30 |

| CBL-400 | Ø 38 | Ø 26 | 142 | 83 | 21 | 13 | 30 |

Product Description

The Copper-Aluminum Terminal integrates an arch-shaped copper palm (rear-square, front-rounded) to optimize torque distribution and mechanical stability in high-vibration systems, precision-bonding ≥99.9% T2 copper and ≥99.5% L3 aluminum via friction welding for zero galvanic corrosion. Pre filled conductive grease chambers and seals maintain ultra-low resistance in environments ranging from -40 ° C to 120 ° C, making them an ideal choice for circuit breakers, automated production lines, and coastal smart grids. Its design has been certified according to ISO 9001 standards. Compared to flat terminals, it reduces shear stress by 35% and has a reliable service life of up to 25 years.